Story

1891

Brothers Milton M. and Bernard P. Wagner of Sidney, Ohio established The Wagner Manufacturing Company. It opened for business in June 1891 with 20 employees on its payroll. Just three months later, it employed 41 men and melted 9,200 pounds of iron daily, with plans to build an addition to the foundry the following year. Cookware, known as hollowware or simply ware at the time, was a growing industry and Wagner would quickly establish itself as a market leader.

-

1892

Wagner registered the first patent for its waffle iron, covering an innovative hinge design by R. O. Bingham. Bingham, a mechanic who served as the company's superintendent, would prove to be a prolific designer and his name can be found on four additional patents for the waffle iron alone.

-

1894

A line of cast aluminum cookware was introduced, a first for the industry. That same year, construction began on a new building, the second addition to Wagner's Sidney plant in just three years of business.

-

1897

Wagner acquired Sidney Hollowware Company, a local competitor. William H. Wagner, brother of Milton and Bernard, sold his hardware store and joined his family in the cookware business. As the eldest brother, William was tasked with running the new foundry and named president of the company.

1902

Additional polishing machines were installed to accommodate the labor intensive process of finishing the castings. Wagner was a pioneer in both nickel plated cast iron and cast aluminum, both of which required extensive grinding and buffing to achieve their signature luster.

-

1904

Wagner was awarded Gold Medal for their cast iron and aluminum cookware on display at the World's Fair in St. Louis. Expositions were a central feature of the company's marketing efforts and it also won awards in Paris, San Francisco and Chicago.

-

1905

The Sidney Hollowware foundry was sold back to Philip Smith, its original owner. Wagner would build a new, larger foundry on the same site as its primary operations the following year to replace its capacity.

-

1908

International distribution of the company's products brought the Wagner brand, and the city of Sidney, global recognition. A navy serviceman from Sidney reported that he found displays of Wagner aluminum cookware in every foreign country he visited.

1912

Another addition to the plant was completed, increasing its size to 160,000 square feet. The plant required a staff of 300 to operate. The Sidney Daily News boasted that their city was home to "the largest Holloware Plant in the World and one of the most up-to-date factories of its kind in existence."

-

1915

The company introduced its iconic Wagner Ware stylized logo, recognizable for the looped W. At the time, branding was not commonplace for manufacturers, and some of Wagner's competitors neglected to mark their products at all. The logo would remain in use for the majority of the brand's history, through multiple ownership changes.

-

1916

After 25 years in business, the Wagner family reflected, "...we have labored without ceasing to produce a line of kitchen ware which we might be proud to identify with our family name...to be distinguished from all other lines not only because of its superior wearing qualities but by reason of the beauty of the design in which it is expressed."

-

1934

The Magnalite line, made with a proprietary magnesium-aluminum alloy, was introduced. It would prove to be a popular collection and remained a staple in the company's catalog for decades to come.

1935

Meanwhile... Following decades on the market with little public interest, electric ranges (stoves) started to gain popularity in the United States. These new appliances were marketed on their ease of use and consistent, predictable heating. An advertisement for the Hotpoint brand proclaimed, "...it cooks entire meals while mother is shopping or busy with housework."

1941

Wagner introduced pre-seasoned cast iron cookware with the catalog description, "It is foolproof...it is safe...it is sensational! It eliminates the old varnish-like lacquer that had to be burned or scoured off."

-

1942

The rationing of aluminum during World War II put restrictions on the production of Magnalite cookware. The residents of Sidney were asked to donate scrap metal with a call to "search for material necessary to win the war."

-

1946

A series of stock transfers took place between members of the Wagner family after the passing of founders Bernard and Milton. Company ownership was consolidated among their heirs.

-

1948

A 4-ton washing machine designed for cleaning Magnalite products after polishing was installed at the plant, marking a gradual shift towards automation. Prior to this, the cleaning process was accomplished individually, by hand.

1950

Meanwhile... Du Pont opened its first commercial polytetrafluoroethylene (PTFE) plant in West Virginia. Marketed under the brand name Teflon, this slippery material was first used in industrial applications. Just one year later, it would begin use in commercial food processing as a nonstick coating, paving the way for the era of modern nonstick cookware.

1952

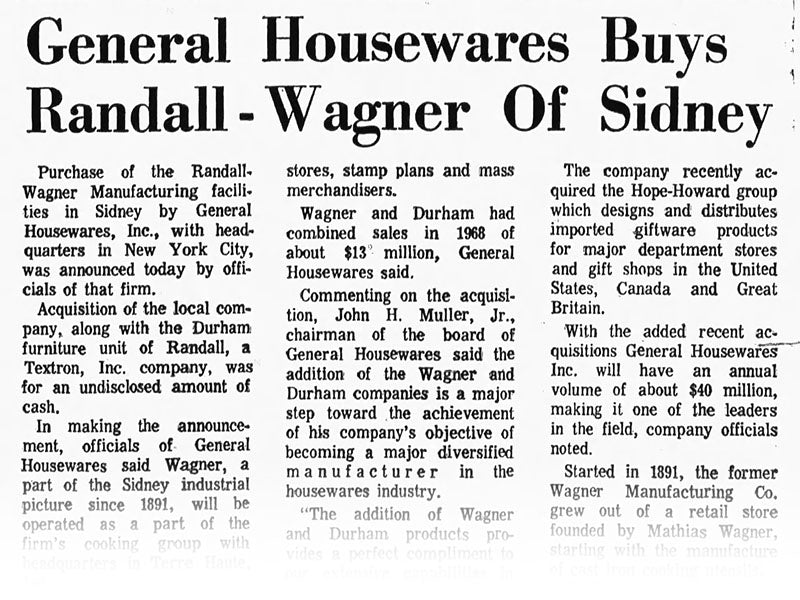

The Wagner family sold their namesake company to The Randall Company of Cincinnati, Ohio, a car parts manufacturer. Jerome and Joseph Wagner, sons of founders Bernard and Milton, respectively, remained on staff as plant managers. For many collectors and enthusiasts, this marks the end of the golden age of the brand and Wagner cookware produced after this time is generally less prized.

-

1957

Randall purchased The Griswold Manufacturing Company of Erie, Pennsylvania, one of Wagner's primary competitors. The two brands would be traded together in future acquisitions.

-

1959

Randall, and Wagner and its subsidiary, was acquired by Textron Incorporated. Under Textron ownership, the brand continued to operate as a division of Randall, its products marketed as Randall Made Wagner Ware.

-

1965

As nonstick cookware gained popularity and widespread use, Wagner introduced a line of cast iron skillets coated with mint green Teflon. An advertisement promised "old fashioned cookability with modern rinse-away washing."

1969

General Housewares Corporation, established just two years prior, bought the Textron housewares line, including Wagner, as part of a series of acquisitions in the housewares market. GHC would prove to be a powerful force in the industry, successfully operating numerous manufacturing locations and distributing its products under an assortment of brands.

-

1974

Modern upgrades were installed at the plant including cupola emission controls to meet new environmental standards, as well as an air filtration system for the health and safety of its 400 employees. By this time, the casting process was largely automated, with the molding line producing five molds per minute.

-

1987

General Housewares discontinued the use of the Wagner Ware trademark and launched a new Wagner product line, confusingly marketed as Wagner's 1891 Original. This new collection featured redesigned handles with a distinctive thumb rest and seasoning instructions cast into the bottom of each piece.

-

1996

General Housewares closed its Wagner division. Following months of uncertainty and negotiations, a group of investors purchased the assets, including the foundry in Sidney. The newly formed group, incorporated under the name Wagnerware Corporation, continued manufacturing cookware at that location.

1999

Wagnerware Corp struggled to find its footing and its stewardship of the brand was short lived. The plant closed for a scheduled break in July 1999 but never reopened and the property fell into receivership. Subsequent, unaffiliated owners abandoned the property shortly thereafter and left the building in disrepair, and no Wagner cookware was produced at that location after the end of the 20th century.

-

2015

The market for new and vintage cast iron cookware grew, bringing Wagner and its contemporaries renewed interest and attention.

-

2019

Historic reference materials were obtained from libraries and private collectors. Product development began for Wagner's next chapter.

-

2021

The Wagner family of Sidney, Ohio, descendants of the founders, joined the project. Their insight, guidance and support would be invaluable for re-launching the brand their ancestors built.

2022

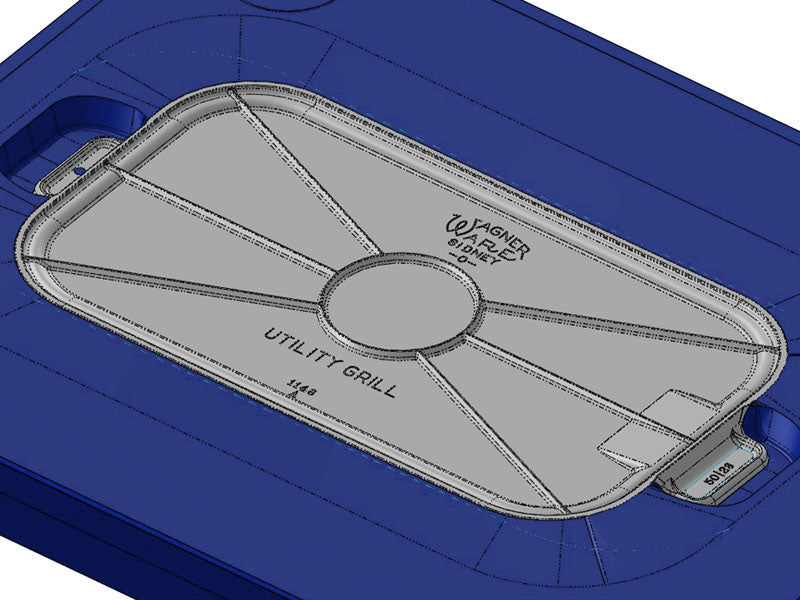

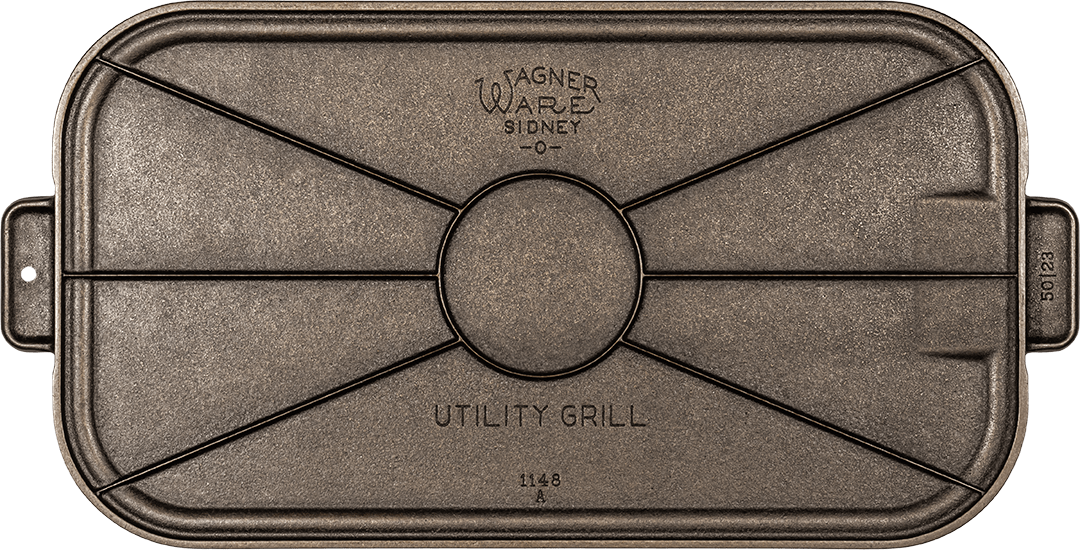

A new generation was introduced to Wagner through a series of reissued products. The vintage designs were studied in exhaustive detail in order to recapture the look, feel and quality of the originals.

Long Griddle No. 1148

This griddle is a functional tribute to the history of American cast iron.